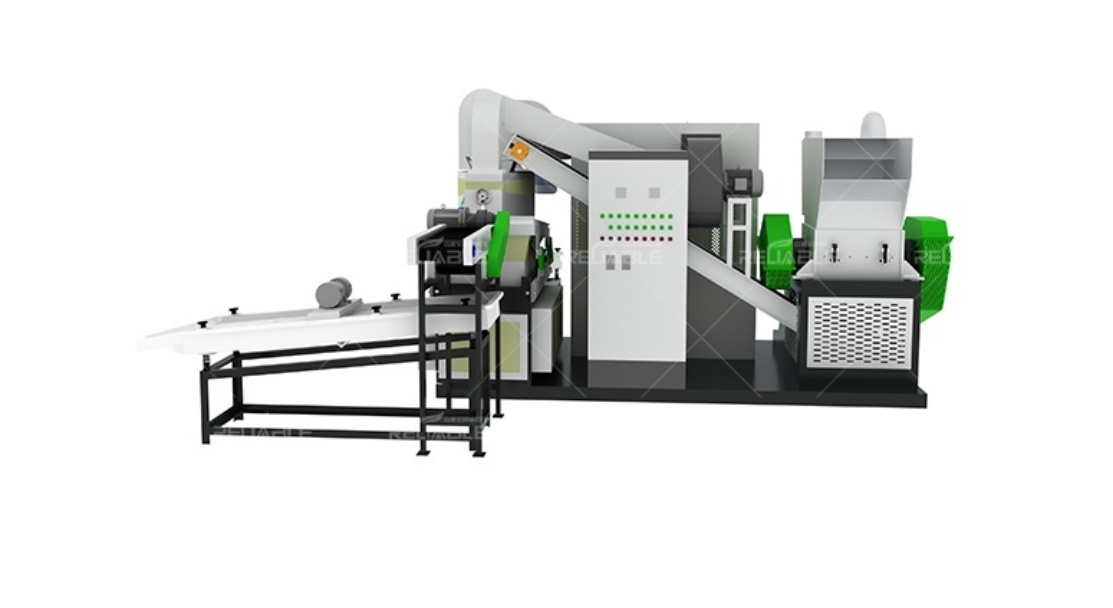

Working Process

The motor drives the cutter head to rotate at high speed, utilizing the gap between the moving and stationary blades to shear and crush the plastic. The final output particle size is controlled by a screen.

Alloy steel blades generate cutting action through high-speed rotation, suitable for hard plastics (e.g., ABS, PE) and soft materials (e.g., film, rubber).

Screen mesh aperture determines output size, typically adjustable to approximately 1 cm to meet diverse recycling requirements.

Equipped with overload protection, soundproof hoppers, and power interlock systems to ensure operational safety and low noise levels

Core Features

High efficiency

adopting high-strength blades and powerful motors to ensure fast crushing speed and high productivity.

Exceptional wear resistance

blades and bearings are manufactured from highly wear-resistant materials, ensuring extended service life.

Intelligent control

equipped with a PLC control system supporting automated operation to enhance production efficiency and equipment stability.

Get a Free, Customized Quote to Suit Your Specific Needs

RELIABLE Complete Care Package: Expert Installation, Rapid Repairs, Ongoing Training – All in One Place. We will design the most suitable equipment to help your recycling business achieve higher efficiency and greater economic benefits.

Get in touch with us today, and let’s start reducing your waste more efficiently and effectively!

Contact now!