Key Applications

Type of Knife

Equipment knife structure

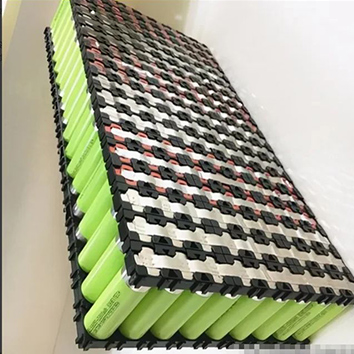

Suitable for tearing heavy metals or thick plastic, such as refrigerators and metal barre Is with at

SW-type knife structure

Try it to tear the general products, such as wood and aluminum engine cases such as fragile or crisp

VZ knife structure

Suitable to tear the thin and light material materials, such as packaging aluminum, car shell, etc

Pineapple knife structure

Suitable for hard plastic such as tearing circuit board, which can tear the material to less than 10

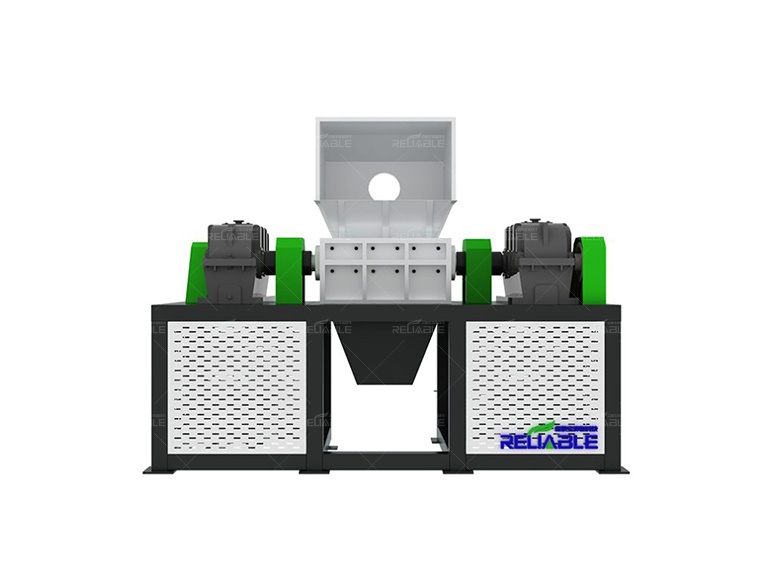

Key Advantages

More – Covering More Recycling Scenarios

- D600: Suitable for small recycling stations, processing capacity 500-600kg/h

- D800: Suitable for medium-sized dismantling plants, processing capacity 700-800kg/h

- D1000: Suitable for metal processing plants, processing capacity 800-1000kg/h

- D1200: Suitable for large recycling centers, processing capacity 1000-1200kg/h

- Actual Measurement Comparison:

3mm cold-rolled steel: D1000 can reach 900kg/h (single-shaft models with the same power only reach 500kg/h) - Aluminum alloy windows: D800 processes 750kg/h (50% higher than single-shaft models)

Faster – 40% Increased Shredding Efficiency

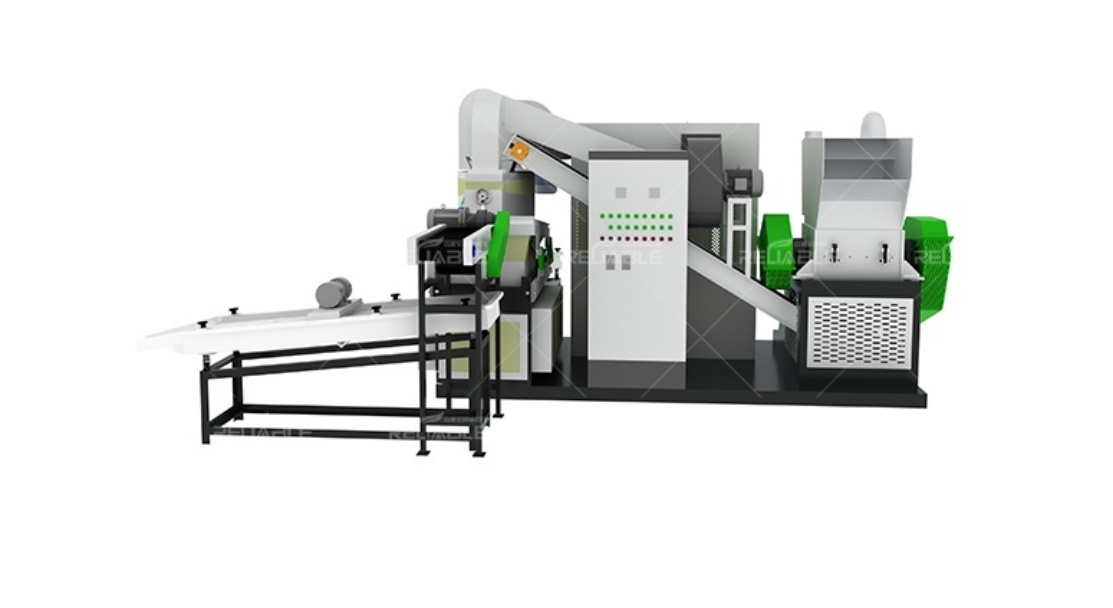

- Our Double Shaft Shredder is equipped with precise power configurations, greatly improving shredding speed:

- D600: 7.5+7.5kw servo motors, main shaft speed 38rpm, secondary shaft 35rpm

- D1200: 30+30kw servo motors, cutting line speed 2.8m/s

- Steel plate shredding time: D800 only takes 9 seconds (single-shaft models take 16 seconds)

- Car wheel hub shredding: D1000 completes ≤50mm in 3 working cycles

Better – High Stability and Long Service Life

This series of Double Shaft Shredders is made from high-quality materials and innovative technology, ensuring stable operation and longer service life:

- Thickened steel plate welding, with a 3D reinforced rib structure, improves impact resistance by 40%, and reduces noise by 12dB.

- Modular quick-change structure, replacing a single blade set takes only 25 minutes (traditional models take 2 hours). SKD11 mold steel blades are vacuum-hardened to HRC62, making them 1.6 times more durable than regular blades.

- Wear-resistant manganese steel liners, reducing wear by 75%, extending the service life to over 5 years.

Cheaper – Lower Maintenance Costs

- The design of RELIABLE’s Double Shaft Shredder focuses on reducing maintenance costs:

- Blade replacement cost: Each D600 is 18% lower than similar products, and D1200 is 22% lower.

- Maintenance cycle: All models require initial maintenance after 500 hours (traditional models after 300 hours).

- Failure statistics: Annual failure rate is 0.35-0.48% (industry average 1.2%).

Why Choose RELIABLE Double Shaft Shredder

Proven Global Success

Our double shaft shredder is trusted in recycling facilities across Europe, Southeast Asia, and South America, proving its reliability and efficiency.

Customizable Designs

RELIABLE offers a range of rotor and blade configurations to meet specific material processing needs, from soft to heavy-duty waste.

Long-Term Investment

Built with durability in mind, our double shaft shredder reduces the frequency of repairs and lowers the total cost of ownership over its long lifespan.

Environmentally Friendly

Our shredder helps businesses meet environmental regulations by converting waste into valuable resources, reducing the need for landfills and contributing to a circular economy.

Contact Us Now to Customize Your Exclusive Double Shaft Shredder Solution!

As a professional manufacturer, RELIABLE has strong design and R&D capabilities to provide tailored Double Shaft Shredder solutions. Whether your goal is to improve metal recycling efficiency or adapt to processing different materials, share your specific needs with us, and we will design the most suitable equipment to help your recycling business achieve higher efficiency and greater economic benefits.

Get in touch with us today, and let’s start reducing your waste more efficiently and effectively!

Contact now!