Type of Knife

Equipment knife structure

Suitable for tearing heavy metals or thick plastic, such as refrigerators and metal barre Is with at

SW-type knife structure

Try it to tear the general products, such as wood and aluminum engine cases such as fragile or crisp

VZ knife structure

Suitable to tear the thin and light material materials, such as packaging aluminum, car shell, etc

Pineapple knife structure

Suitable for hard plastic such as tearing circuit board, which can tear the material to less than 10

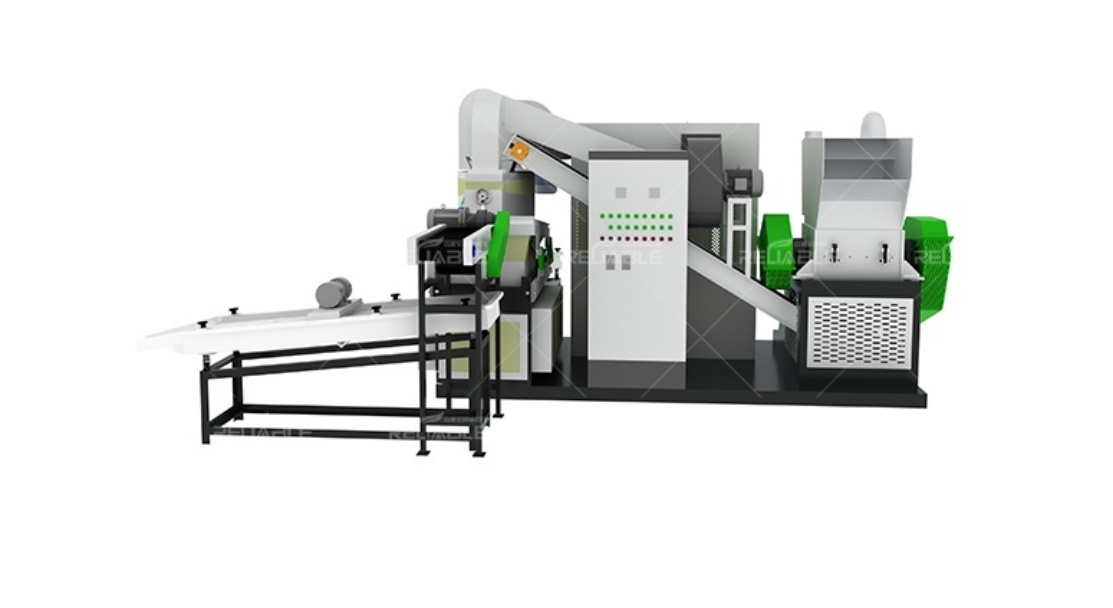

Versatile Adaptation to Various Tires

Whether it’s steel-wire tires, fiber tires, or giant OTR tires, the RELIABLE Tire Shredder handles them all effortlessly. No frequent parameter adjustments are required; the equipment automatically adapts to different tire types, optimizing the recycling process and producing high-quality 50mm rubber granules, paving the way for subsequent recycling.

Processing Technology

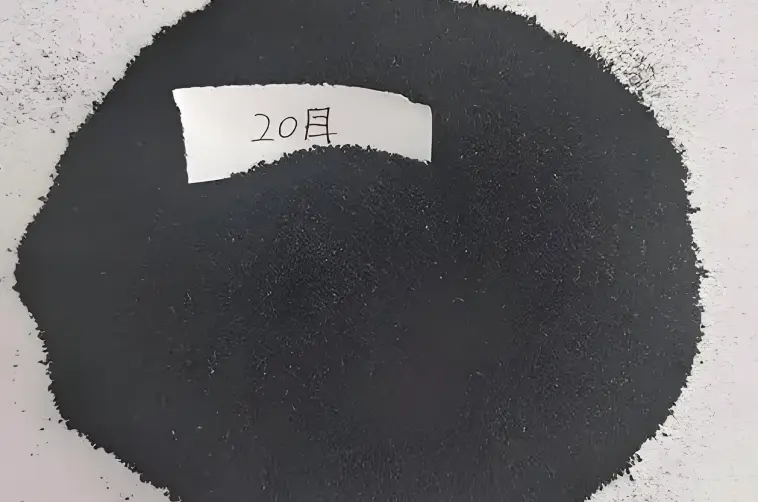

After shredding waste tires, the rubber is processed into powder and widely used in sports synthetic turf fields, playgrounds, rubber tiles, waterproof coatings, rubber products, and other applications.

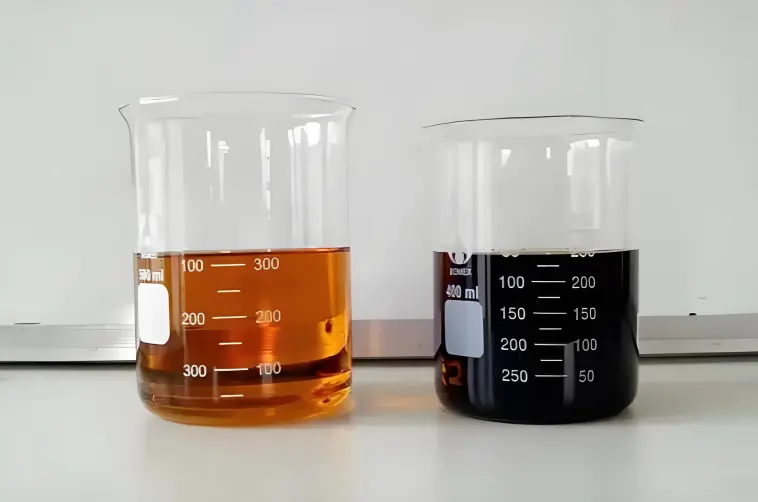

Tire Pyrolysis Refining: The pyrolysis of waste tires involves shredding and grinding the tires, followed by heating them under pyrolysis technology. Through precise control of temperature and pressure, this process converts waste tires into resource-recycled products such as fuel oil, carbon black, and steel wire.

After shredding and impurity removal (e.g., steel wire extraction), waste tires are processed into granular fuel (TDF). This fuel can be directly used in industrial facilities such as cement kilns and power plant boilers as a substitute for coal.

Customer Cases and Feedback

“After using it for half a year, the processing capacity has increased by 40% compared to before!” This is the real feedback from our European customers about our tire shredders. After switching to our shredder, the processing speed of truck tires increased from 2 tons per hour to 3.5 tons per hour, and the maintenance costs were significantly reduced.

In India, in high-temperature and dusty conditions, ordinary equipment often breaks down. Our rubber tire recycling machine, with its special protective design, operates stably even at 45°C, easily handling large volumes of used motorcycle and truck tires. They have now placed an additional order for 2 more units.

Why Choose RELIABLE

Efficient and Stable

RELIABLE tire shredders are running stably at recycling centers around the world, providing continuous value growth for customers.

Customized Solutions

We offer personalized designs based on different waste tire materials and recycling needs, ensuring the equipment meets your specific demands.

Long-Term Investment Returns

With low maintenance frequency and high durability, our machines help you reduce operational costs and generate higher returns.

Want to optimize recycling efficiency and boost your business profits?

Click to contact us and customize your RELIABLE tire shredder solution, unlocking a new experience in efficient recycling!

Get in touch with us today, and let’s start reducing your waste more efficiently and effectively!

Contact now!