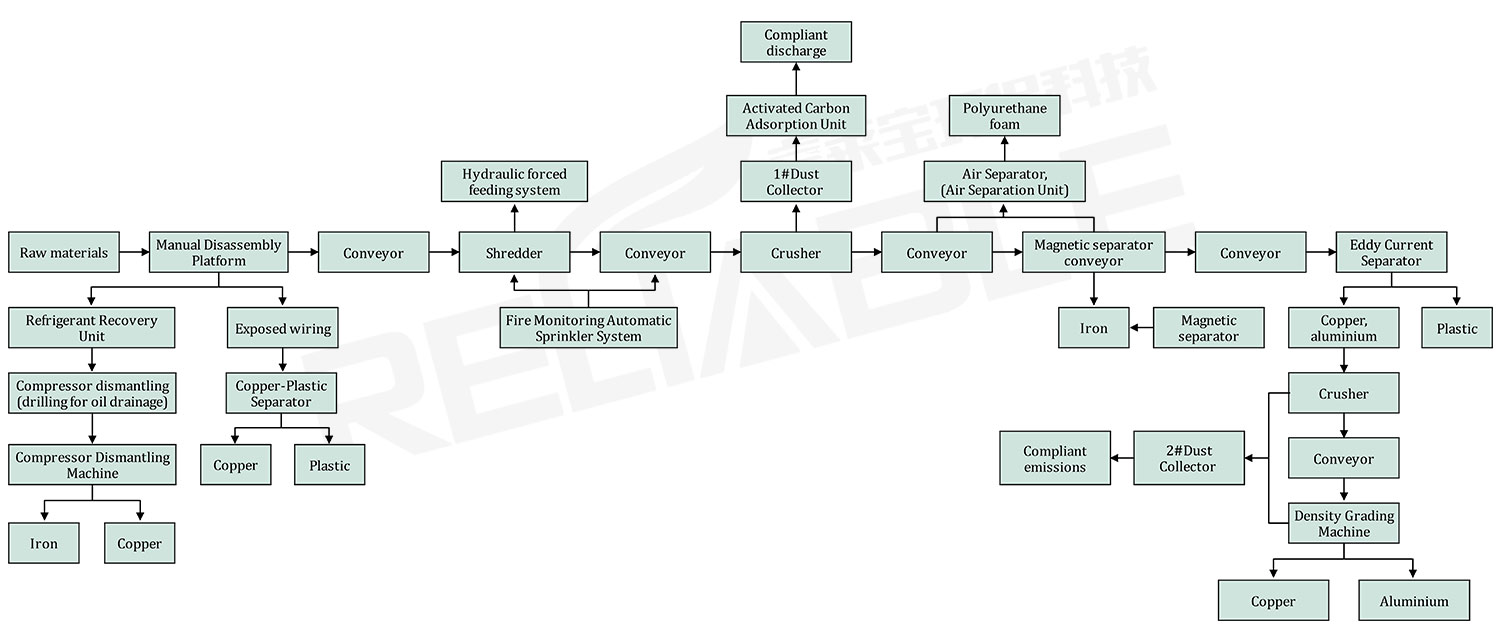

Recycling Process

- Using specialized double-shaft refrigerator shredders and two-stage vertical refrigerator crushers for crushing operations.

- During the crushing stage, adopting air separation equipment and specialized structures for bubble wrap removal and dust control;

- Separating ferrous metals (primarily iron-containing materials) using magnetic separation equipment.

- Separating non-ferrous metals and non-metals via eddy current separation equipment. Implement centralized dust collection and activated carbon gas filtration for harmless treatment, achieving a complete process of shredding and sorting waste refrigerators.

Why Choose Our Refrigerator Recycling Production Line

Central Pulse Dust Collection System

The central pulse dust collection system centrally collects dust generated during production, with emissions below 8 mg/m³, meeting national standard GB/Z2.1-2007.7.

Enhanced Sorting Efficiency

The integrated vertical crushing and grinding system separates materials while rolling metallic particles into spherical shapes, increasing bulk density and improving sorting efficiency.

Strong Magnetic Drum Separation System

This system separates iron and steel from materials while controlling the purity of steel products. Its unique operating mechanism minimizes impurity adhesion during separation.

Full PLC Control

Full PLC Control with Dynamic Real-Time Monitoring.

Contact RELIABLE for Your Custom Refrigerator Solution

RELIABLE Complete Care Package: Expert Installation, Rapid Repairs, Ongoing Training – All in One Place. We will design the most suitable equipment to help your recycling business achieve higher efficiency and greater economic benefits.

Get in touch with us today, and let’s start reducing your waste more efficiently and effectively!

Contact now!