Solar Panel Recycling Process

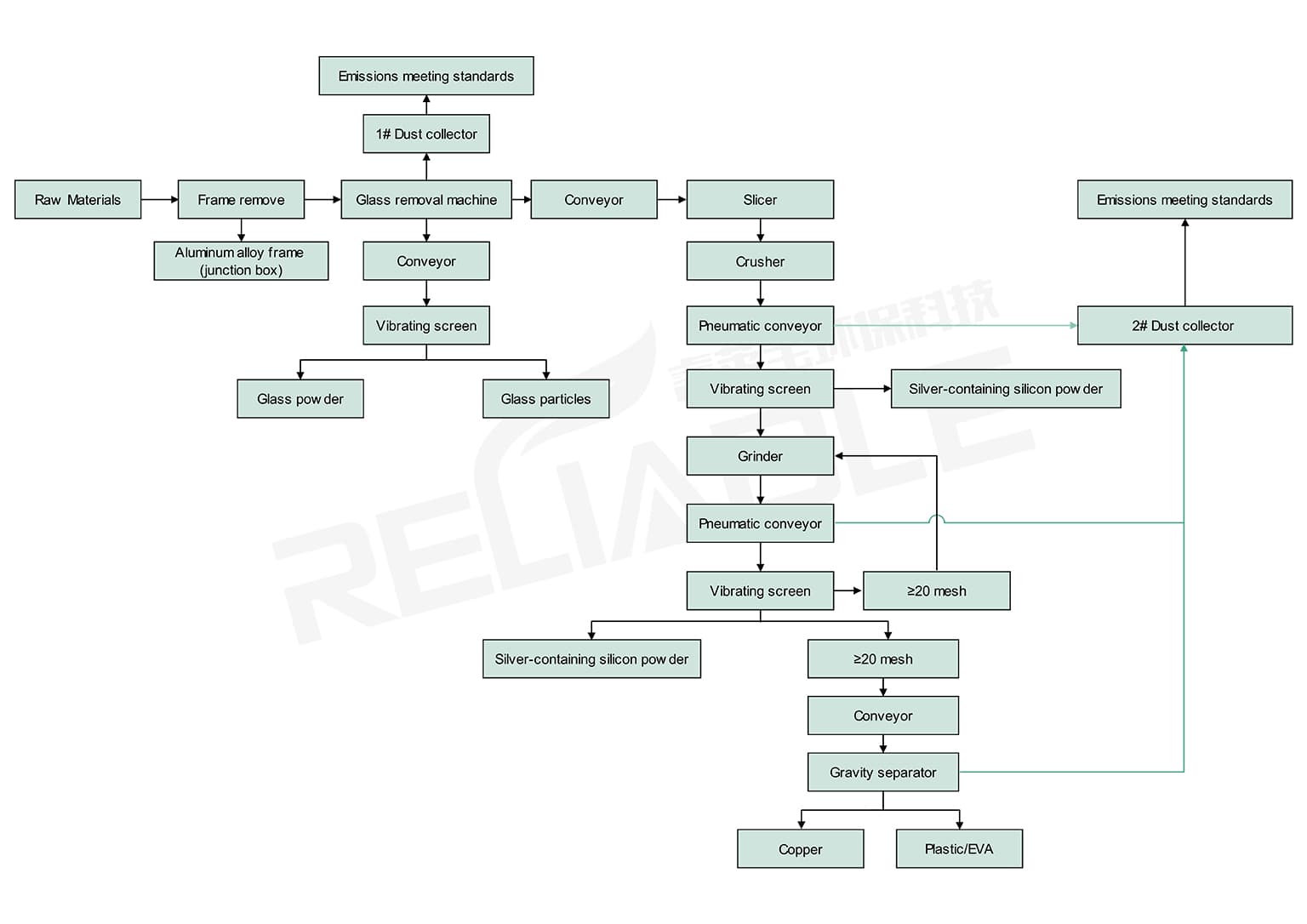

- Frame Removal: The PV panel frame removal machine uses compression to push out and separate the aluminum alloy frame, facilitating subsequent processing. Aluminum frame removal rate >99%, with a recycling purity >98%.

- Glass Removal: The glass layer is removed using a hot knife peeling method, exposing the core components of the solar cell and backsheet. Glass removal rate is 98%, with a recycling purity of 98%.

- Crusher: Shreds or further pulverizes the cells into granular particles.

- Screening Equipment: Separates materials into distinct fractions—silicon powder containing silver, copper-plastic mixtures, etc.—via vibrating screens.

- Sorting System: Utilizes air classification, density separation, and other methods to segregate copper, silicon, plastics, and other materials.

Why Choose Our Solar Panel Recycle Line

Maximized Material Recovery Efficiency

Silicon powder can be further purified – increasing resale value by 30%

Aluminum frames are 100% recyclable – cutting raw material costs up to 40%

High-grade glass can be directly reused – no extra processing required

Flexible Layout & Custom Design

Suitable for both industrial-scale operations and small recycling centers Modular design allows future upgrades and seamless integration

Wide Compatibility with Solar Waste

Handles crystalline silicon, thin-film, broken modules, and production leftovers Complete solution from disassembly to fine sorting

Reliable Support & Service

One-year warranty on the entire Solar Panel Recycle Plant Lifetime technical support and fast spare parts delivery worldwide

Contact RELIABLE for Your Custom Solar Panel Recycle Solution

RELIABLE Complete Care Package: Expert Installation, Rapid Repairs, Ongoing Training – All in One Place. We will design the most suitable equipment to help your recycling business achieve higher efficiency and greater economic benefits.

Get in touch with us today, and let’s start reducing your waste more efficiently and effectively!

Contact now!